Glue machine GM-20

※Structural features:

★after quenched of the glue roller surface,the hole machining, surface grinding and doing balancing engraved anilox pit type, coating evenly, less consumption of plastic

★glue roller turns is controlled by the frequency motor,by inverter control ensures glue roller line speed synchronous machine with double machine,they can operate independently。

★electric adjustment display the glue amount。Automatic cycle for glue, glue avoid sedimentation, viscosity stability。

★Pneumatic structure platen gap by electric tuning。On the next floor are made independent variable frequency motor drive。

★take the speed signal of the double facer,so as to synchronous operation with it. Man-machine interface display, easy operation

★amount of glue automatic adjustment control,amount of glue automatic adjustment with the produce speed, in automatic mode, you can also get in manual tuning.

※Technical parameters:

1、the highest design speed:200m/min

2、the Max. width:2200mm

3、air source system:0.4—0.6Mpa

4、operation direction:left or right(determined by customer’s factory)

※Roller diameter parameters:

1、glue roller:¢269mm doctor roller:¢142mm

2、press paper shaft:¢155mm

3、 over paper roller diameter:¢110mm

※Powered motor parameters:

1、glue roller initiative motor:3KW 380V 50Hz Continuous (S1) working standard

2、glue adjustment reducer: 100W 380V 50Hz short(S2)working system

3、pressure roller gap adjustment motor: 100W 380V 50Hz short(S2)working system

4、glue pump motor: 2.2KW 380V 50Hz Continuous (S1)working system

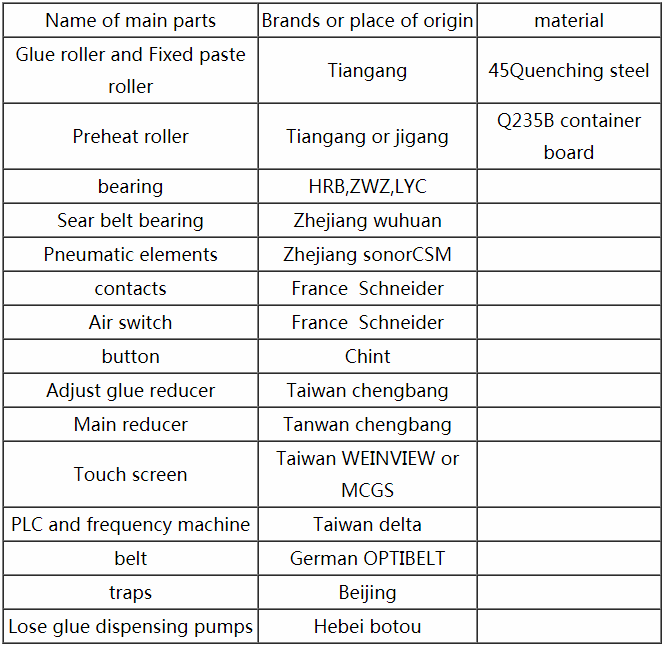

※Mainly purchased parts, raw materials and origin: